Technical Information Polypropylene Random

Why choose this type of material? The thermoplastic resins most often used to make pipes for water and heating systems are:- PE-X Cross linked polyethylene.

- PP-C Polypropylene co polymer. PB Polibutene.

All the above- mentioned resins belong to the polyolephine family, a group of plastic materials obtained by polymerization of unsaturated hydrocarbons, which have one or more double links.

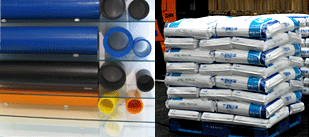

Raw Material

The raw material used in the manufacture of HANZEL PPRC Pipes & Fittings is the Korean raw material HYOSUNG R200P. This raw material is obtained by cracking petroleum where by propen monomer polymerizes with polypropleyene co monomer to form POLYPROPYLENE RANDOM CO POLYMER referred to as Type-3 PPRC. HYOSUNG R200P is a top grade raw material where-in; during extrusion the molecules are stretched to provide rigidity with high molecular weight fulfilling the requirements to with stand high temperature and pressure. The process of manufacture of HANZEL PPRC pipes & fittings confirms to international standards of DIN 8077/8078 & DIN 16962 where-in the finished products are subjected to attest by Sweden Body cote polymer AB Institution for a duration of 8760 Hours.R200P

Since 1998, Hyosung Corp. has been leading supplier of PP for PP-R pipe in the world with the brand of ‘TOPILENE R200P’.

With continuous product development to meet market requirements, in 1998 Hyosung launched R200P, high molecular weight low-MFR polypropylene-ethylene random copolymer. R200P is recommended for pressure pipe manufacturing and injection moulding of fittings for use at elevated temperatures.

It is available in natural, gray, green, white, and blue colors. Even though the sales initiated in the Middle east and Turkey, it soon became biggest share in Asian market. Now, R200P is used all around the world like Europe, South-America, Asia and Africa.

Advantage

Technology Which Provides HANZEL PP-RC PIPE SYSTEM

HANZEL produces PPRC (Polypropylene Random Co Polymer) Pipes & Fittings with High Korean technology compatible to DIN 8077-8078 & DIN 16962 standards, with using HYOSUNG R200P. The greatest specialty about HYOSUNG R200P raw material is its extremely safe usage in the hot water pipes as it has brilliant resistance against heat and chemical substances. The products which are produced from this raw material are hygienic and agreeable to the nutriment charter because it is not also affected by any biological substances. It is certified by Health Ministries of European Union countries that PPRC Type 3 raw material is healthy and hygienic. It is completely Non Toxic and complies with food grade as per the current standards at international level. The increasing use of PPRC in the field of packing confirms the hygienic quality of the raw material. This guarantees HANZEL PPRC PIPE SYSTEM as the optimal packing for one of our most precious commodity goods - The Potable Water.FEATURES

- Strong & Long Lasting. Hygienic & Non-Toxic.

- No Rust, No Scaling & Resistant to Abrasion - Corrosion. Highly Resistance to Acids & Chlorides.

- Light Weight & No Maintenance. Extremely Low Thermal conductivity

- Easy Installation & Handling. Insulation is not required for Interior Applications. Tolerates High Pressure & Temperature.

- Low Pressure Drop. Eco-Friendly & Not Harmful to Human Health. Noise Free at High Flow Rates.

- Approved by Water Quality Institutes of 16 Countries. Extensive Saving in both Time & Labour.

- No Calcification and Sedimentation. Un-Effected by Termites. Widely used in European & Developed Countries.

- Resistant to Stray Electric Currents.

- No Bacterial or Fungal Growth and No Contamination. Highly Flexible and Competitive Price.

Pressure Test I Test Control

According to the Technical Rules for Potable Water Installations DIN 1988 all pipelines have to be (while still visible) hydraulically pressure tested. The test pressure has to be 1.5 times of the operating pressure. When carrying out the pressure test the material properties of HANZEL-pipes may lead to an expansion of the pipe. This influences the test result. A further influence of the test result can be caused by the coefficient of thermal expansion of HANZEL pipes. Different temperatures of pipe and test medium lead to alterations of pressure. A temperature change of 10 K corresponds to a pressure difference of 0.5 to 1 bar. Therefore the highest possible constant temperature of the test medium has to be ascertained at the hydraulic pressure test of installations with HANZEL-Pipes. The hydraulic pressure test requires a preliminary, principal and final test. For the preliminary test a test pressure of 1.5 times of the highest possible operating pressure has to be produced. This test pressure has to be re-established twice within 30 minutes within an interval of 10 minutes. After a test time of further 30 minutes the test pressure must not drop more than 0.6 bar and no leakage should have appeared. The preliminary test is to be followed directly by the principal test. Test time is 2 hours. On doing so the test pressure taken from the preliminary test may not fall more than 0.2 bar. After completion of the preliminary and principal test the final test must be conducted, which has to effected with a test pressure of alternate 10 and 1 bar in a rhythm of at least 5 minutes Between each test course the pressure has to be removed.Measuring of the Test Pressure

After every installation and lying of pipe, pressure test has to be conducted depending on temperature required. A record of the hydraulic pressure test has to be prepared and signed by the client and contractor stating place and date. Measuring has to be done with a manometer allowing a perfect reading of a pressure change of 0.1 bar. The manometer has to be placed at the deepest point of the installation.Hydrostatic Pressure Performance

With all water carrying pipes, resistance to internal pressure is an important factor, which affects long life characteristics. Therefore to assure the optimum in long life performance, straight and curved HANZEL pipes have been subjected to extensive hydrostatic pressure testing at a variety of different temperatures The results, and the success of these tests can be seen in the Table 1. To plot the ydrostatic pressure performance graph independently of dimensions, the hoop stress(O) is calculated according to the formula:(0=p(de-e)) / 2e

P = Internal pressurede = the external pipe diameter of pipe (mm)

e = The wall thickness of the pipe (mm)

Our Facilities

-

Made

of High brass

-

Contains

65% Copper and 35% Zinc

-

High

tensile strength and is corrosion resistant

-

Brass

is coated with chromium which helps to reduce friction

-

Add wear

resistance and to increase corrosion resistance

-

PPRC fittings

can withstand temperature up to 95°C and pressure upto 25kg/cm2