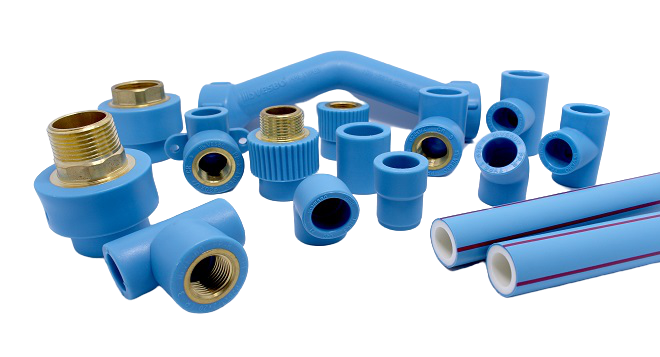

We are pleased to be introducing HANZEL PPRC PIPE SYSTEM before you as we know that our products ranging from 20mm to 160mm with more than 450 different fittings can fulfill your entire needs while pipe installations. An association means long years of mutual co-operation on the basis of trust & Responsibility and is much more for us as "The customer’s success and satisfaction is our success" and we are confident that you will feel the difference after using HANZEL PPRC PIPE SYSTEM. HANZEL Pipes & Fittings are manufactured in accordance with ISO 9001-2000 Quality Management system and are used and accepted worldwide for both Hot & Cold circulation system of potable water, oils and other fluids in domestic applications as well industrial segments. HANZEL PP-RC pipes are available in five category/class according to pressure capability.

The silent features of HANZEL PPRC PIPE system are:

- It can be used for transportation of water and other fluids of temperature up to 140°c.

- The low thermal conductivity of HANZEL pipes makes the product excellent for hot water circulation.

- The linear expansion and contraction is negligible even in open installation up to 47°c.

- HANZEL PPRC PIPE SYSTEM is Hygienic, Non-Toxic Rust and Scale freemaking it ideal for Drinking water purposes.

- Taste and odour neutral.

- Excellent weld ability.

- Bacteriologically neutral.

- Physiologically harmless.

Raw Material

The raw material used in the manufacture of HANZEL PPRC Pipes & Fittings is the Korean raw material HYOSUNG R200P. This raw material is obtained by cracking petroleum where by propen monomer polymerizes with polypropleyene co monomer to form POLYPROPYLENE RANDOM CO POLYMER referred to as Type-3 PPRC. HYOSUNG R200P is a top grade raw material where-in; during extrusion the molecules are stretched to provide rigidity with high molecular weight ulfilling the requirements to with stand high temperature and pressure. The process of manufacture of HANZEL PPRC pipes & fittings confirms to international standards of DIN 8077/8078 & DIN 16962 where-in the finished products are subjected to atest by Sweden Body cote polymer AB Institution for a duration of 8760 Hours.R200P

Since 1998, Hyosung Corp. has been leading supplier of PP for PP-R pipe in the world with the brand of ‘TOPILENE R200P’.History

It is available in natural, gray, green, white, and blue colors. Even though the sales initiated in the Middle east and Turkey, it soon became biggest share in Asian market. Now, R200P is used all around the world like Europe, South-America, Asia and Africa.

Advantages

Technology Which Provides HANZEL PP-RC PIPE SYSTEM

HANZEL produces PPRC (Polypropylene Random Co Polymer) Pipes & Fittings with High Korean technology compatible to DIN 8077-8078 & DIN 16962 standards, with using HYOSUNG R200P. The greatest specialty about HYOSUNG R200P raw material is its extremely safe usage in the hot water pipes as it has brilliant resistance against heat and chemical substances. The products which are produced from this raw material are hygienic and agreeable to the nutriment charter because it is not also affected by any biological substances. It is certified by Health Ministries of European Union countries that PPRC Type 3 raw material is healthy and hygienic. It is completely Non Toxic and complies with food grade as per the current standards at international level. The increasing use of PPRC in the field of packing confirms the hygienic quality of the raw material. This guarantees HANZEL PPRC PIPE SYSTEM as the optimal packing for one of our most precious commodity goods - The Potable Water.Fields of Application

The polypropylene random co polymer pipe system from HANZEL can be used for:- Chilled water networks in the Air conditioning systems.

- Pipe networks for rain water utilization systems.

- Pipe networks for compressed-air plants.

- Pipe networks for swimming pools facilities.

- Pipe networks for solar plants.

- Pipe networks in agriculture, horticulture sectors and for gardens.

- Pipe networks for industry, i.e. for transport of aggressive fluids, wide range of chemicals and liquid foods.

Features

- Strong & Long Lasting. Hygienic & Non-Toxic.

- No Rust, No Scaling & Resistant to Abrasion - Corrosion. Highly Resistance to Acids & Chlorides.

- Light Weight & No Maintenance. Extremely Low Thermal conductivity

- Easy Installation & Handling. Insulation is not required for Interior Applications. Tolerates High Pressure & Temperature.

- Low Pressure Drop. Eco-Friendly & Not Harmful to Human Health. Noise Free at High Flow Rates.

- Approved by Water Quality Institutes of 16 Countries. Extensive Saving in both Time & Labour.

- No Calcification and Sedimentation.Un-Effected by Termites. Widely used in European & Developed Countries.

- Resistant to Stray Electric Currents.

- No Bacterial or Fungal Growth and No Contamination. Highly Flexible and Competitive Price.

About PP-R

Advantages

Comparison with Other Pipe Systems

| Pex-Al-Pex Pipe | HANZEL | ||||||

| Property / Pipe Style | G.I Pipe | Copper Pipe | UPVC Pipe | CPVC Pipe | P.B Pipe | ||

| Service Life | 5-10 Years | 25 Years | 25 Years | 25 Years | 50 Years | 50 Years | 100 Years |

| Resistance to High Temperature | Very Good | Very Good | Bad | Common | Very Good | Good | Very Good |

| Hygienic Property | Bad | Common | Bad | Common | Very Good | Very Good | Very Good |

| Recyclable and No Pollution | No | No | No | No | Yes | Yes | Yes |

| Pipe Furring | Yes | Yes | No | No | No | No | No |

| Common-Resistant | Bad | Bad | Very Good | Very Good | Very Good | Good | Very Good |

| Installation | Hard | Hard | Easy | Easy | Easy | Easy | Easy |

| Price | Average | High | Low | High | High | High | Average |

| Reliability | Common | Common | Common | Common | Common | Common | Very Good |

Our Facilities

-

Ranging

from 20mm to 160mm with more than 450 different fittings

-

Association

means long years of mutual co-operation

-

Success & Satisfaction

the customer’s success and satisfaction is our success

-

Transportation Fluids

It can be used for transportation of water and other fluids of temperature up to 140°c

-

Thermal Conductivity

the low thermal conductivity of HANZEL pipes makes the product excellent for hot water circulation

-

SYSTEM is Hygienic

HANZEL PPRC PIPE SYSTEM is Hygienic, Non-Toxic Rust and Scale freemaking it ideal for Drinking water purposes